Demand Quality Control for Massachusetts Precision Machining

If you don’t care about the quality of the finished products that you get from Massachusetts machining and assembly, there are hundreds of local shops that you can hire. However, if your goal is to work with a precision machine shop that takes pride in the work that they do and strives to continuously improve on the work that they do, come to AMI Machining. Our machine shop employs a team of highly trained, skilled, and experienced engineers and technicians who are specialized in Massachusetts precision machining and assembly. Veteran owned and ITAR registered, we have the technical expertise and manufacturing capacity to assist with just about any type of application. Whether you require standard or custom work, simple or complex designs, large or small orders, you can count on AMI Machining to meet or exceed expectations.

If you don’t care about the quality of the finished products that you get from Massachusetts machining and assembly, there are hundreds of local shops that you can hire. However, if your goal is to work with a precision machine shop that takes pride in the work that they do and strives to continuously improve on the work that they do, come to AMI Machining. Our machine shop employs a team of highly trained, skilled, and experienced engineers and technicians who are specialized in Massachusetts precision machining and assembly. Veteran owned and ITAR registered, we have the technical expertise and manufacturing capacity to assist with just about any type of application. Whether you require standard or custom work, simple or complex designs, large or small orders, you can count on AMI Machining to meet or exceed expectations.

Effective Quality Management Systems

We work hard to meet the production deadlines and quality requirements of our clients by implementing quality management systems that exceed industry standards. Our mission is to always deliver quality results and adhere to each client’s budget requirements. We apply the industry’s best practices at every phase of development and manufacturing, to provide our customers with on-time service and unmatched quality production. A significant portion of our resources has been dedicated to lean manufacturing. Our custom production team utilizes the various tools, concepts, and methods employed by lean manufacturing to help us maintain a strong position and stay on the cutting edge of Massachusetts precision machining.

As a one-stop source for all of your Massachusetts machining and assembly requirements, our team has the knowledge, training, experience, and equipment necessary to provide excellent quality control for complete electro-mechanical assembly work. We specialize in the machining of precision components and work with a variety of industries. Some of the clients that we serve come from aerospace, defense, military, electronics, telecommunications, medical devices, semiconductors, and other industries, providing our team with a wide range of challenges and experiences to draw on for the work we do for other clients. We are ISO 9001 certified and provide 100 percent verification at each production interval for continuous in-process inspection.

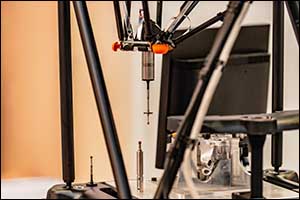

Quality Control Equipment – Some of the equipment that we use in our Massachusetts precision machining facility includes Coordinate Measuring Machines (CMMs), such as the Bendix Cordax 1000 and the Zeiss Contura G2. We use these to ensure robust and precise measurements with the benefit of computer-aided accuracy to guarantee quality machining and manufacturing. Our team also relies on the J&L EPIC 14 optical comparator for the inspection of manufactured parts. This tool helps us to ensure that the dimensions and geometry of the machining and manufacturing that we do are accurate. We utilize several different varieties of height gauges, including the MICRO-HITE and HITE from Tesa, including the 14, 24, and 28-inch models.

Custom Production and Prototyping

Our custom production team works with your engineers to help in the development of prototypes. The sooner we can start working with you in the early design phases of the project, the easier it will be for us to help you meet all of your machining and production deadlines, ensure quality management systems for best results, and meet all of your budgetary requirements. Our state-of-the-art facility features many different types of high-value advanced equipment. We use CNC machining equipment for both long and short-run part milling, as well as CNC turning lathe centers for large-diameter turning at close tolerances. We are committed to combining the latest technology and equipment with the industry’s best practices to provide our clients with the best possible results.

We believe strongly in attracting and cultivating the best talent in the business at our precision machine shop. We invest in our employees, offering continued training and exposure to new technology. Each member of our team has the knowledge and background necessary to deliver results for Massachusetts machining and assembly that exceed expectations. Our value-added electro-mechanical assembly and precision machining offer our clients quality services that they just can’t find anywhere else. We serve customers right here in Massachusetts and throughout the New England region at our one-stop machining and assembly facility. Our solutions are designed to save our clients time and money, reducing manufacturing costs while providing continuous process improvements.

If you would like to learn more about our Massachusetts precision machining and assembly services, contact our team by calling 508-947-1192. We can answer any questions about our state-of-the-art climate-controlled facility, advanced equipment for precision machining, and rapid response program for prototyping and flexibility. Located in Middleboro, Massachusetts, our skilled team of technicians and engineers work together with each client to deliver custom manufacturing solutions.